IEC 62304 + ISO 14971 for SaMD: How to Integrate Lifecycle & Risk

- Beng Ee Lim

- May 27, 2025

- 3 min read

Updated: Sep 7, 2025

Integrate IEC 62304 (software lifecycle) with ISO 14971 (risk management) by mapping hazards → requirements → design → tests → evidence. Use one traceability matrix that ties the risk file to SRS/SDS and V&V, then carry it into eSTAR sections for your 510(k)/De Novo. This yields regulator-friendly documentation without adding process overhead.

Why These Standards Matter Together

IEC 62304 gives you the “how” of building medical software—planning, requirements, design, implementation, verification, release, maintenance.

ISO 14971 gives you the “how” of identifying and controlling risks throughout a medical device’s lifecycle—hazard analysis, risk evaluation, risk control, residual-risk evaluation, and post-market surveillance.

For SaMD teams, these standards aren’t separate—they’re two halves of one FDA expectation—you must show not only what you built but how you managed every risk.

FDA reviewers look for:

Lifecycle documentation (per IEC 62304)

Risk files and control verification (per ISO 14971)

Clear mapping between the two

If you're building software that diagnoses, monitors, or treats—both standards apply.

High-Level Comparison: Where They Align

IEC 62304 Activity | ISO 14971 Clause | Key Deliverable |

Software Development Planning | Risk Management Planning | Risk-linked software plan with owners |

Requirements & Architecture | Hazard Identification | Hazard log + preliminary risk analysis |

Implementation & Testing | Risk Control Verification | Test cases aligned to control measures |

Release, Maintenance, Patching | Postmarket Surveillance | Incident reports & CAPA integration |

Step-by-Step Integration Guide

🔹 Step 1: Create a Combined Traceability Matrix

Start with your Software Requirements Specification (SRS).

For each software requirement, link:

Associated hazards (ISO 14971)

Corresponding risk controls

Aligned test cases (IEC 62304)

Maintain this matrix as your single source of truth for regulatory audits.

🔹 Step 2: Embed Risk Management into Design Reviews

At every design phase gate, explicitly review:

Hazard logs and risk evaluations (FMEA, Annex C of ISO 14971)

Status of mitigation implementation

Any residual risks and their justifications

Document all decisions in design review records.

🔹 Step 3: Align V&V Protocols with Risk Controls

Each risk control must have a dedicated test case with:

Clear pass/fail criteria

Direct traceability to the originating hazard

Proof of control effectiveness, not just functionality

This ensures your V&V satisfies both standards.

🔹 Step 4: Integrate Maintenance & Post-Market Feedback

Use IEC 62304 processes to track:

Software updates, bug fixes, and patch logs

Field incidents and complaint trends

Feed this data back into your risk management file and update CAPA actions per ISO 14971.

Real-World Example: “Hypothetical SaMD X”

SRS ID | Functionality | Hazard | Control | Test ID |

SRS-12 | Auto-detection of AFib via ECG sensor | False negative = missed stroke | Real-time alert + human review | T-12.1 |

The Fastest Path to Market

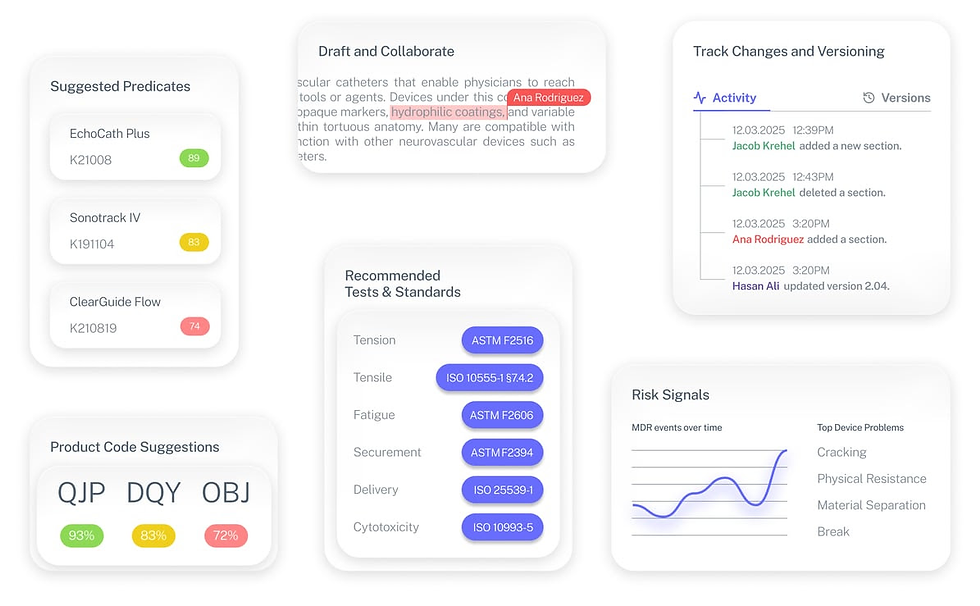

No more guesswork. Move from research to a defendable FDA strategy, faster. Backed by FDA sources. Teams report 12 hours saved weekly.

FDA Product Code Finder, find your code in minutes.

510(k) Predicate Intelligence, see likely predicates with 510(k) links.

Risk and Recalls, scan MAUDE and recall patterns.

FDA Tests and Standards, map required tests from your code.

Regulatory Strategy Workspace, pull it into a defendable plan.

👉 Start free at complizen.ai

FAQs

Q: Do I need both standards for FDA SaMD submissions?

Yes. FDA reviewers expect software process compliance (IEC 62304) and full risk documentation (ISO 14971).

Q: Can ISO 14971 replace IEC 62304?

No. They serve different purposes—risk management vs. development lifecycle.

Q: How often should I update the risk management file?

Update at every major release, patch, or when new risks/complaints emerge.

Key Takeaways

Integrate early: build your traceability matrix before coding.

Keep docs in sync: link every test back to a hazard.

Plan maintenance: feed real-world data into your CAPA process.

For deeper guidance, visit our SaMD Compliance hub or learn how to define your Device Software Function.