The Hidden Costs of Non-Compliance: How Medical Device Companies Can Avoid Regulatory Pitfalls

- cemguler3

- Sep 12, 2024

- 5 min read

Updated: Sep 7, 2025

Non-compliance with FDA regulations can significantly damage medical device companies, both financially and operationally. In this article, we’ll dive into the hidden costs of non-compliance, how regulatory pitfalls can affect companies, and how leveraging tools like Complizen can help avoid these risks.

Understanding Non-Compliance

Non-compliance occurs when companies fail to meet FDA requirements, including FDA medical device guidelines, GMP guidelines, and documentation practices. It’s a common problem for medical device companies, especially startups, as navigating the FDA's complex regulations can be overwhelming.

If ignored, non-compliance can lead to costly delays and legal ramifications. Understanding the full scope of compliance—from FDA registration to documentation and method validation—can help businesses stay on track.

Non-Compliance with FDA Regulations Impacts Your Bottom Line

Financial losses due to non-compliance go beyond fines. Medical device companies often face expensive recalls, delayed product launches, and missed revenue opportunities for revenue, which can ultimately affect market positioning.

Learn more about how to avoid these issues in our guide on FDA Registration for Medical Devices.

How Non-Compliance Can Drive Hidden Financial Losses:

Delayed Approvals: Products can’t reach the market on time, leading to lost revenue.

Legal Fees: Companies face lawsuits or penalties due to violations.

Market Recalls: Non-compliant products may need to be pulled, damaging finances and reputation.

Operational Pitfalls in Medical Device Non-Compliance

Beyond financial implications, operational efficiency suffers when non-compliance occurs. Halting production lines or launching a recall due to non-compliance with FDA GMP guidelines can lead to significant downtime. This not only impacts internal teams but also affects suppliers, distributors, and even customers.

Common Regulatory Mistakes Medical Device Companies Make

Many companies fall victim to common regulatory mistakes, such as:

Incorrect FDA Registration: Not completing FDA device registration accurately.

Inconsistent Good Documentation Practices: Failure to maintain proper records leads to compliance audits or delays.

Mislabeling or Poor Validation Practices: Errors in labeling or failing to adhere to FDA method validation guidelines can cause costly rejections.

The Importance of FDA Compliance for Medical Device Companies

FDA compliance is more than a legal necessity—it's a critical element of a company’s business strategy. By complying with the FDA’s GMP guidelines and maintaining good documentation practices, companies can avoid regulatory pitfalls and get products to market faster.

Key Areas Where Medical Device Companies Struggle with Compliance

Many medical device companies, especially small to medium-sized enterprises (SMEs), struggle with the following compliance challenges:

Complexity of FDA Documents: Understanding and interpreting complex FDA medical device guidelines is often challenging.

Good Documentation Practices: Not adhering to these standards can result in poor audit results and longer approval timelines.

FDA Registration: Incomplete or incorrect registrations often lead to delays or denials.

Financial Penalties for Non-Compliance

Delays in Product Launches Due to Non-Compliance

A delay in product launches can be just as costly as a penalty.

Medical device companies must go through rigorous FDA reviews, and any misstep in the submission process can push a product launch back by months. Delays result in lost market share and can also negatively impact your company’s reputation among investors and customers.

How Non-Compliance Can Damage Your Brand Reputation

Medical device companies operate in a high-stakes environment. A single non-compliance issue can tarnish your brand's image, particularly if it leads to a product recall. Trust is crucial in this sector, and once damaged, it’s hard to regain.

Companies that fail to meet FDA medical device guidelines or make critical errors during FDA device registration often face reputational harm, impacting both current and future business prospects.

FDA Registration and Good Documentation Practices

Good documentation practices (GDP) ensure every detail about the product’s manufacturing process is logged, which can be essential for FDA audits. Additionally, proper FDA registration requires accuracy and completeness. Following these practices ensures that medical devices can be approved faster, with less risk of non-compliance.

FDA GMP Guidelines and Their Role in Compliance

Adhering to FDA GMP guidelines ensures that your product meets the required safety and quality standards. This not only reduces the risk of costly recalls but also ensures that patients and healthcare providers can trust your product.

How to Avoid FDA Non-Compliance for Medical Devices

Staying compliant with FDA guidelines requires a proactive approach:

Thorough Training: Ensure all employees understand the FDA GMP guidelines.

Routine Audits: Regular internal audits can identify potential issues before they escalate.

Documentation: Keep clear and accurate documentation to avoid problems during FDA reviews.

Use Technology: Leverage tools like Complizen for better compliance tracking. Learn more about the role of AI in FDA compliance on our recent blog post.

Using FDA Consultants and FDA Agents to Navigate Regulations

For medical device companies, navigating FDA regulations typically requires working with FDA consultants. While consultants can still play a valuable role, Complizen simplifies much of the compliance process by offering document retrieval and interpretation tools. This allows companies to handle many tasks internally, reducing reliance on external help and saving time.

For foreign companies, a US Agent is mandatory to interact with the FDA. Complizen provides this service as part of its platform, ensuring seamless communication with the FDA and helping companies stay compliant.

The Fastest Path to Market

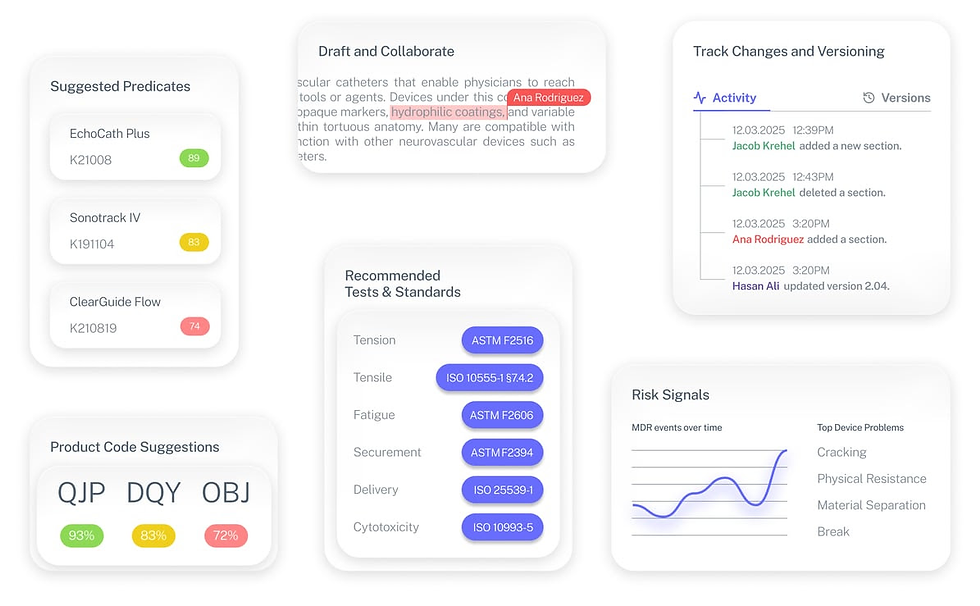

No more guesswork. Move from research to a defendable FDA strategy, faster. Backed by FDA sources. Teams report 12 hours saved weekly.

FDA Product Code Finder, find your code in minutes.

510(k) Predicate Intelligence, see likely predicates with 510(k) links.

Risk and Recalls, scan MAUDE and recall patterns.

FDA Tests and Standards, map required tests from your code.

Regulatory Strategy Workspace, pull it into a defendable plan.

👉 Start free at complizen.ai

Conclusion

Non-compliance with FDA regulations can result in devastating financial and operational consequences. However, companies that take proactive steps, such as using tools like Complizen and hiring FDA consultants, can avoid these pitfalls. From reducing delays to preventing costly recalls, staying compliant ensures a smoother path to market success.

FAQs

1. What are the hidden costs of non-compliance for medical device companies?

Non-compliance can lead to delays, legal fees, product recalls, and financial penalties that go beyond the initial fine.

2. How can Complizen help with FDA compliance?

Complizen simplifies FDA compliance by offering instant access to relevant FDA documents and connecting users with consultants and agents.

3. Why are good documentation practices important?

Good documentation ensures that all processes are logged correctly, facilitating faster audits and FDA reviews.

4. What are FDA GMP guidelines?

These are guidelines that ensure the consistent production of quality medical devices, reducing the risk of recalls and defects.

5. How does non-compliance impact product launches?

Non-compliance can lead to delayed product launches, missed revenue opportunities, and increased competition.

6. Do foreign medical device companies need an FDA agent?

Yes, all foreign medical device companies, regardless of size, are required by the FDA to have a US Agent. The US Agent acts as a liaison between the company and the FDA, facilitating communication and ensuring compliance with regulatory requirements.

7. How can I avoid common regulatory pitfalls?

Staying informed, adhering to good documentation practices, and using compliance tools like Complizen are key to avoiding pitfalls.