Pre-market Approval (PMA) Explained: The Complete 2025 Guide

- Jun 20, 2025

- 9 min read

Updated: Sep 7, 2025

Premarket Approval (PMA) is FDA’s most rigorous pathway, used for most Class III devices (those that support/sustain life, prevent major impairment, or pose potential unreasonable risk). A PMA must demonstrate reasonable assurance of safety and effectiveness with nonclinical and clinical evidence; FDA may conduct a manufacturing (QSR) inspection and sometimes an advisory-panel review.

Understanding PMA requirements early in development can save you years of delays and millions in development costs. This guide explains the PMA process in straightforward terms, helping you determine if your device needs PMA and what to expect from this demanding regulatory pathway.

What Is PMA (Pre-market Approval)? The Simple Answer

Pre-market Approval (PMA) is FDA's scientific review process for Class III medical devices—the highest-risk category of medical devices. Unlike 510(k) clearance, which relies on substantial equivalence to existing devices, PMA requires comprehensive clinical evidence proving your device is safe and effective for its intended use.

Think of PMA as FDA saying: "This device is so critical to patient safety that we need complete scientific proof it works as intended before allowing it on the market."

Why PMA Exists

FDA created PMA for devices that pose the highest risk to patients—typically life-sustaining, life-supporting, or implantable devices. These devices require the highest level of regulatory scrutiny because device failure could result in serious injury or death.

The PMA standard is "reasonable assurance of safety and effectiveness," which requires:

Comprehensive clinical data demonstrating device performance

Rigorous manufacturing controls ensuring consistent quality

Detailed risk-benefit analysis showing benefits outweigh risks

Post-market surveillance to monitor ongoing device performance

Which Devices Require PMA?

Most Class III medical devices require PMA approval before marketing. These are typically devices that support or sustain human life, are implanted in the body, or present unreasonable risk of illness or injury.

Examples of Devices That Typically Require PMA:

Cardiovascular Devices: Pacemakers and implantable defibrillators, Heart valves and vascular grafts, Left ventricular assist devices (LVADs), Coronary stents (some types)

Neurological Devices: Deep brain stimulators, Spinal cord stimulators, Implantable neurostimulators, Some epilepsy treatment devices

Orthopedic Implants: Hip and knee replacement systems, Spinal fusion hardware, Bone growth stimulators, Some trauma fixation devices

Ophthalmology Devices: Intraocular lenses, Retinal implants, Corneal transplant devices

Life-Support Equipment: Certain ventilators, Heart-lung bypass machines, Some dialysis equipment

Devices That Usually Don't Require PMA:

Class I and Most Class II Devices: Surgical instruments, Diagnostic equipment, Most medical software, External monitoring devices

510(k)-Exempt Devices: Simple medical devices with established safety profiles, Devices substantially equivalent to pre-1976 devices

How to Determine If Your Device Needs PMA

Check FDA's Product Classification Database to determine your device's regulatory pathway:

Search by device name or product code

Review the classification and regulation number

Check if PMA is required in the device description

Look for guidance documents specific to your device type

If your device is novel or doesn't fit existing classifications, FDA may require a De Novo petition to establish appropriate regulatory controls.

The PMA Process: Step by Step

Phase 1: Pre-Clinical Development (1-3 years)

Before human testing, develop comprehensive pre-clinical evidence:

Device Design and Development:

Finalize device design and manufacturing processes

Establish design controls and quality systems

Conduct comprehensive bench testing and validation

Perform biocompatibility testing for patient-contacting materials

Animal Testing (If Required):

Design animal studies to evaluate safety and performance

Conduct Good Laboratory Practice (GLP) studies

Generate data supporting transition to human studies

Address any safety concerns before clinical trials

Manufacturing Validation:

Establish manufacturing processes and controls

Validate sterilization and packaging methods

Demonstrate manufacturing consistency and quality

Prepare for commercial-scale production

Phase 2: Clinical Trial Planning (6-12 months)

Clinical trials are almost always required for PMA devices:

Investigational Device Exemption (IDE):

Submit IDE application to FDA before starting clinical trials

Describe study protocol, device design, and safety measures

Obtain Institutional Review Board (IRB) approval

Train clinical investigators and monitor study conduct

Clinical Trial Design:

Design studies to demonstrate safety and effectiveness

Determine appropriate endpoints and success criteria

Calculate required sample sizes for statistical significance

Plan for multiple study phases if needed

Phase 3: Clinical Trials (1-5 years)

Conduct clinical studies to generate effectiveness data:

Pilot Studies:

Small studies (20-100 patients) to evaluate initial safety

Refine device design based on early clinical feedback

Establish preliminary effectiveness signals

Identify potential safety concerns

Pivotal Trials:

Large studies (100-1,000+ patients) demonstrating effectiveness

Randomized controlled trials comparing to standard of care

Long-term follow-up to assess device durability

Multi-center studies to demonstrate broad applicability

Post-Market Studies (May Be Required):

Continue monitoring device performance after approval

Assess long-term safety and effectiveness

Study device performance in broader patient populations

Phase 4: PMA Submission Preparation (6-12 months)

Compile comprehensive PMA application:

Clinical Data Analysis:

Analyze all clinical trial data for safety and effectiveness

Perform statistical analysis demonstrating device performance

Compare results to appropriate control groups

Address any safety signals or adverse events

Manufacturing Information:

Document complete manufacturing processes and controls

Provide facility information and quality system details

Include device labeling and instructions for use

Demonstrate manufacturing consistency and validation

Phase 5: FDA Review Process (6-18 months)

Submit PMA and undergo FDA scientific review:

Administrative Review (45 days):

FDA determines if submission is complete for substantive review

Missing information requests may delay review start

FDA assigns review team and establishes review timeline

Scientific Review (180+ days):

FDA conducts comprehensive review of clinical and technical data

Multiple FDA divisions may participate in review process

FDA may request additional information or studies

Advisory panel meeting may be required for novel devices

FDA Decision:

Approval with or without conditions

Approvable letter requiring specific changes

Not approvable letter identifying deficiencies

Denial (rare, usually after multiple revision attempts)

Types of PMA Applications

Original PMA

Used for completely new devices without FDA-approved predecessors:

Requirements:

Complete clinical trial data demonstrating safety and effectiveness

Comprehensive manufacturing and quality information

Detailed device description and intended use

Risk analysis and benefit-risk assessment

Review Timeline: 6-18 months after submission acceptance

Success Rate: Ultimate approval rates now exceed 90 %, but only ~30-40 % of PMAs clear on the first review cycle.

PMA Supplement

Used for changes to already-approved PMA devices:

Panel-Track Supplement:

Significant changes requiring clinical data

New indications or patient populations

Major design or manufacturing changes

Review timeline: 180+ days

180-Day Supplement:

Moderate changes with supporting data

Labeling changes with clinical impact

Manufacturing changes affecting safety or effectiveness

Review timeline: 180 days

Minor changes with minimal risk impact

Administrative labeling changes

Manufacturing changes not affecting device performance

Review timeline: Typical FDA decision in ~60 days; there is no statutory clock, but the process is designed for a single, interactive review meeting.

Allows submission of PMA sections over time rather than all at once:

Benefits:

Earlier FDA feedback on study design and data requirements

Reduced risk of major submission problems

Opportunity to address FDA concerns before final submission

Requirements:

Pre-submission meetings to establish modular approach

Structured submission timeline agreed upon with FDA

Complete final module must still meet full PMA requirements

PMA vs. Other FDA Pathways

Understanding how PMA compares to other FDA pathways helps you choose the right approach for your device. More here.

PMA Costs and Timeline Planning

Typical PMA Development Costs

FDA User Fees (2025):

Standard business: $540,783 for original PMA

Small business: $135,196 for original PMA

Development and Clinical Costs (Estimation):

Pre-clinical development: $1-5 million

Clinical trials: $5-50 million (depending on complexity)

Regulatory consulting: $500,000-$2 million

Manufacturing validation: $1-5 million

Total typical cost: $10-100 million+

Pre-Clinical Phase: 1-3 years (design, testing, animal studies)

Clinical Trials: 2-5 years (pilot studies, pivotal trials)

PMA Preparation: 6-12 months (data analysis, submission writing)

FDA Review: 6-18 months (review, potential revisions)

Total Timeline: 4-8+ years from concept to approval

Factors That Affect Cost and Timeline

Faster/Less Expensive:

Device modifications to existing approved devices

Well-established clinical endpoints and study designs

Experienced clinical and regulatory teams

Clear FDA guidance for device category

Slower/More Expensive:

First-in-class devices requiring novel clinical approaches

Complex multi-component systems

Rare conditions requiring specialized clinical expertise

International regulatory requirements adding complexity

Common PMA Challenges and Solutions

Insufficient Clinical Evidence

The most common reason for PMA delays or denials is inadequate clinical data.

Common Problems:

Underpowered studies that don't demonstrate effectiveness

Inappropriate control groups or study designs

Insufficient follow-up time to assess device durability

Missing safety data for important patient subgroups

Solutions:

Invest in Pre-Submission meetings to align with FDA on study design

Use appropriate statistical methods and sample size calculations

Plan for longer follow-up periods than initially anticipated

Consider advisory panel feedback when designing trials

Manufacturing and Quality Issues

FDA expects robust manufacturing controls for PMA devices.

Common Problems:

Inadequate manufacturing validation and process controls

Inconsistent device performance across manufacturing lots

Insufficient quality system documentation

Manufacturing changes during clinical trials without proper validation

Solutions:

Implement comprehensive quality systems early in development

Validate manufacturing processes before starting clinical trials

Maintain detailed documentation of all manufacturing changes

Consider FDA Quality System Inspection readiness throughout development

Inadequate Risk-Benefit Analysis

FDA requires clear demonstration that device benefits outweigh risks.

Common Problems:

Insufficient characterization of device risks

Inadequate comparison to existing treatment options

Missing analysis of risk mitigation strategies

Unclear benefit quantification for patient populations

Solutions:

Conduct thorough risk analysis using ISO 14971 principles

Clearly define and quantify patient benefits in clinical terms

Compare your device to all relevant treatment alternatives

Engage clinical experts who understand current treatment limitations

PMA Post-Market Requirements

Ongoing FDA Obligations

PMA approval comes with significant post-market responsibilities:

Submit comprehensive annual reports summarizing device performance

Include adverse event data, complaint trends, and corrective actions

Report manufacturing changes and quality system updates

Provide updates on post-market studies if required

Report device malfunctions that could cause death or serious injury

Manufacturers must submit an MDR within 30 days of becoming aware of a reportable event

A 5-day report is required only if remedial action is needed to prevent serious public-health risk.

Maintain complaint files and investigate all reported problems

Implement corrective and preventive actions as needed

Complete any post-market studies required as condition of approval

Submit periodic progress reports and final study results

Modify device labeling based on post-market findings if required

PMA Supplements for Changes

Most changes to PMA devices require FDA approval through PMA supplements:

Changes Requiring Supplements:

New indications for use or patient populations

Significant design or manufacturing changes

Labeling changes with clinical implications

Manufacturing site changes or major process modifications

Change Planning:

Plan for PMA supplement costs and timelines when making changes

Consider cumulative impact of multiple changes on approval timeline

Maintain change control documentation for all device modifications

The Fastest Path to Market

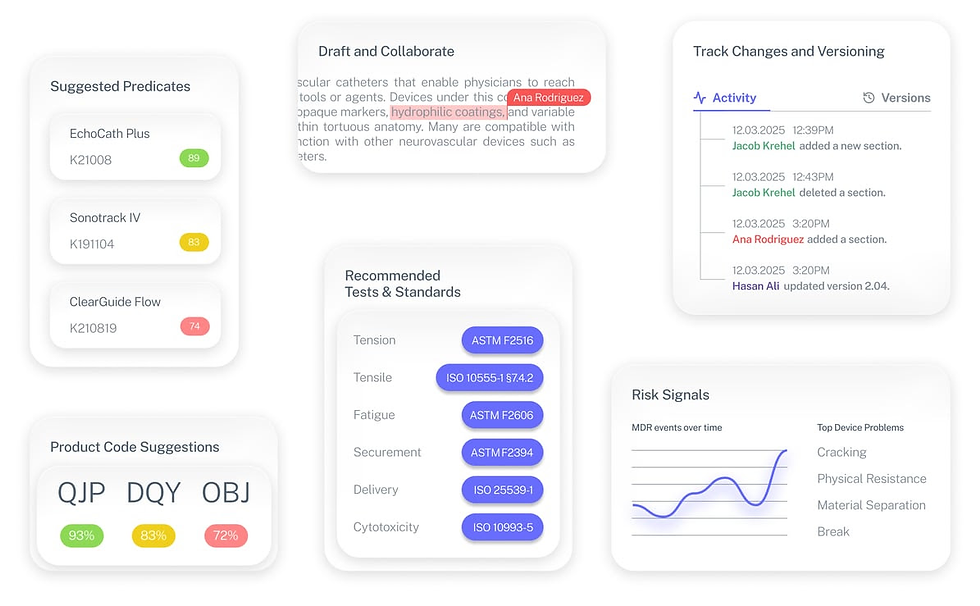

No more guesswork. Move from research to a defendable FDA strategy, faster. Backed by FDA sources. Teams report 12 hours saved weekly.

FDA Product Code Finder, find your code in minutes.

510(k) Predicate Intelligence, see likely predicates with 510(k) links.

Risk and Recalls, scan MAUDE and recall patterns.

FDA Tests and Standards, map required tests from your code.

Regulatory Strategy Workspace, pull it into a defendable plan.

👉 Start free at complizen.ai

Frequently Asked Questions

Q: Can I start selling my PMA device while under FDA review?

A: No. PMA devices cannot be marketed until FDA grants approval. Limited distribution is possible under Investigational Device Exemption (IDE) for clinical trials only.

Q: What happens if FDA denies my PMA?

A: FDA denial is possible. You can request a meeting to discuss FDA's concerns, address deficiencies, and potentially resubmit. Some companies pivot to different indications or patient populations based on FDA feedback.

Q: How do I know if my device needs clinical trials?

A: Nearly all PMA devices require clinical trials. The scope depends on device risk and available predicate data. Pre-Submission meetings with FDA help clarify clinical requirements early.

Q: Can foreign clinical data support a US PMA?

A: Yes, FDA accepts foreign clinical data if studies meet FDA's Good Clinical Practice standards and are relevant to the US patient population. Many companies conduct international trials to reduce costs and timelines.

Q: What's the difference between PMA approval and clearance?

A: PMA devices receive "approval" based on safety and effectiveness evidence. 510(k) devices receive "clearance" based on substantial equivalence. Approval requires more rigorous evidence than clearance.

Key Takeaways

PMA is FDA's most rigorous device pathway reserved for the highest-risk medical devices. It requires comprehensive clinical evidence proving safety and effectiveness.

Clinical trials are almost always required for PMA devices. Plan for 2-5 years of clinical development and $5-50 million in clinical costs.

Timeline planning is critical with total development taking 4-8+ years from concept to approval. Adequate funding for the entire journey is essential.

FDA user fees are substantial at $540,783 for standard businesses and $135,196 for small businesses, plus much higher development costs than other pathways.

Post-market obligations are extensive including annual reports, adverse event reporting, and potential post-market studies.

Early FDA engagement is crucial through Pre-Submission meetings to align on clinical requirements and avoid costly development mistakes.

Next Steps

Considering PMA for your device? Start with device classification confirmation and early FDA engagement to understand requirements.

Need PMA development strategy? Complizen's regulatory experts have guided numerous successful PMA approvals and can help you navigate this complex pathway efficiently.

Schedule a PMA strategy consultation or access our PMA development toolkit to plan your approval strategy.

Successful PMA approval requires early planning, adequate resources, and expert guidance. Our team helps you develop winning PMA strategies from concept through approval.