ISO 14971:2019 Risk Management for Medical Devices: 2025 Implementation Guide

- Beng Ee Lim

- Jul 17, 2025

- 10 min read

Updated: Sep 7, 2025

ISO 14971:2019 is the international standard that defines the lifecycle risk-management process for medical devices (including SaMD): identify hazards, estimate/evaluate risk, implement/verify risk controls, and monitor production & post-production information to keep risks under control. Use ISO/TR 24971:2020 for practical methods and documentation tips; FDA aligns through ISO 13485/QMSR and recommends ISO 14971 in software submissions.

This comprehensive guide provides medical device manufacturers with practical implementation strategies, ensuring regulatory compliance while improving product safety and development efficiency.

ISO 14971:2019 vs 2007: Critical Changes You Must Know

The 2019 edition introduced fundamental changes that many manufacturers still haven't fully implemented:

Major Structural Changes

New Chapter Organization:

Grew from 9 to 10 main clauses

Enhanced clarity in risk management process steps

Improved alignment with ISO 13485 requirements

Better integration guidance for quality management systems

Benefit-Risk Analysis Introduction: The 2019 standard introduces the concept of medical benefit and requires manufacturers to perform benefit-risk analysis when risks cannot be reduced to acceptable levels through design or protective measures.

Key Definition - Medical Benefit: "Positive impact or desirable outcome of the use of a medical device on the health of an individual, or a positive impact on patient management or public health."

Enhanced Post-Market Requirements

Continuous Monitoring Obligations:

Systematic collection and analysis of post-market data

Regular review of risk management activities

Updated risk assessments based on field experience

Documentation of risk management effectiveness

Information Sources for Post-Market Surveillance:

Customer complaints and feedback

Field corrective actions and recalls

Clinical data and adverse events

Manufacturing and quality data

Regulatory reporting requirements

Risk Control Hierarchy Clarification

Updated Risk Control Measures (in priority order):

Inherent safety by design - Eliminate hazards through design

Protective measures - Reduce risks through safety systems

Information for safety - Warnings, training, and instructions

This hierarchy emphasizes that information alone cannot adequately control high-severity risks.

ISO 14971 Implementation Framework: Step-by-Step Process

ISO 14971 serves as the cornerstone of medical device safety management globally. Risk management is a regulatory requirement—without performing risk management and meeting the requirements of ISO 14971, the doors to most major medical device markets worldwide, including the US and EU, are closed.

The standard defines risk as "the combination of the probability of occurrence of harm and the severity of that harm," focusing specifically on patient safety rather than business risks. It covers all medical device types, including Software as a Medical Device (SaMD) and in vitro diagnostic (IVD) devices.

Phase 1: Risk Management Planning (Weeks 1-2)

1.1 Establish Risk Management Policy

Define organizational commitment to risk management

Assign competent personnel and resources

Establish risk acceptability criteria

Create risk management procedures

1.2 Risk Management Plan Development

Identify applicable standards and regulations

Define device intended use and reasonably foreseeable misuse

Establish risk management activities and timelines

Create risk management file structure

1.3 Risk Acceptability Criteria

Organizations must establish objective criteria for determining acceptable risk levels. The standard doesn't specify acceptable risk levels—manufacturers must define these based on:

Device classification and intended use

State-of-the-art practices for similar devices

Regulatory requirements and guidance

Clinical evidence and literature

Phase 2: Risk Analysis (Weeks 3-6)

2.1 Hazard Identification Systematic identification of potential hazards associated with the device:

Common Medical Device Hazards:

Biological hazards: Biocompatibility, infection, toxicity

Chemical hazards: Material toxicity, degradation products

Physical hazards: Mechanical failure, sharp edges, entrapment

Electrical hazards: Shock, burns, electromagnetic interference

Thermal hazards: Excessive heat, cold injury

Radiation hazards: Ionizing and non-ionizing radiation

2.2 Risk Estimation For each identified hazard, estimate:

Probability of occurrence: How likely is the hazardous situation?

Severity of harm: What are the potential consequences?

Risk level: Combination of probability and severity

Risk Estimation Methods:

Qualitative assessment (Low, Medium, High)

Semi-quantitative scoring (1-5 scales)

Quantitative analysis (when data available)

Fault tree analysis for complex systems

Failure mode and effects analysis (FMEA)

Phase 3: Risk Evaluation (Weeks 7-8)

3.1 Risk Acceptability Assessment

Compare estimated risks against predetermined acceptability criteria:

Broadly acceptable: Risks requiring no further action

Tolerable: Risks requiring risk control measures

Unacceptable: Risks requiring immediate action before use

3.2 Risk Control Decision Making

For risks that aren't broadly acceptable:

Apply risk control measures according to hierarchy

Perform benefit-risk analysis if risks remain high

Document rationale for risk acceptability decisions

Phase 4: Risk Control (Weeks 9-12)

4.1 Risk Control Measure Implementation

Apply control measures following the established hierarchy:

Inherent Safety by Design Examples:

Use biocompatible materials

Implement fail-safe mechanisms

Design connectors that prevent misconnection

Eliminate sharp edges and pinch points

Protective Measures Examples:

Install safety interlocks and alarms

Implement software safety features

Add protective barriers or guards

Include automatic shut-off mechanisms

Information for Safety Examples:

Comprehensive instructions for use

Training requirements for users

Warning labels and symbols

Contraindications and precautions

4.2 Risk Control Effectiveness Verification

Verify that control measures reduce risk as intended

Ensure control measures don't introduce new hazards

Document verification methods and results

Update risk analysis based on control measure effectiveness

Phase 5: Residual Risk Evaluation (Weeks 13-14)

5.1 Residual Risk Assessment

After implementing control measures, re-evaluate remaining risks:

Calculate residual risk levels

Compare against acceptability criteria

Perform benefit-risk analysis if needed

Document residual risk acceptability rationale

5.2 Benefit-Risk Analysis

When residual risks aren't acceptable, perform benefit-risk analysis:

Identify and quantify medical benefits

Compare benefits against residual risks

Determine if benefits outweigh risks

Document analysis methodology and conclusions

Phase 6: Risk Management Report (Week 15)

6.1 Risk Management Report Contents

Summary of risk management activities

Conclusion that residual risks are acceptable

Benefit-risk analysis results (if applicable)

Overall risk management effectiveness assessment

6.2 Risk Management Review

Independent review of risk management activities

Verification of risk management plan compliance

Assessment of risk management file completeness

Approval for product release

Integration with Quality Management Systems

ISO 14971 is designed to integrate seamlessly with ISO 13485 quality management systems:

Design and Development Integration

ISO 13485 Section 7.3.3 Requirements:

Risk management outputs must be design and development inputs, ensuring:

Risks are considered from initial design phases

Risk control measures influence design decisions

Risk management activities are documented in design files

Risk analysis updates trigger design change controls

Design Controls and Risk Management Alignment:

Design inputs: Include risk management requirements

Design outputs: Incorporate risk control measures

Design verification: Verify risk control effectiveness

Design validation: Confirm overall risk acceptability

Design changes: Trigger risk management updates

Production and Post-Production Integration

Manufacturing Risk Management:

Production process risk analysis

Supplier risk assessment and control

Non-conforming product risk evaluation

Corrective and preventive action (CAPA) integration

Post-Market Surveillance Integration:

Complaint handling and risk assessment

Field corrective actions and risk updates

Vigilance reporting and risk communication

Management review of risk management effectiveness

Post-Market Surveillance Requirements

The 2019 edition significantly enhanced post-market surveillance obligations:

Continuous Monitoring System

Required Data Collection:

Customer complaints and user feedback

Field corrective actions and recalls

Clinical performance data

Manufacturing and quality issues

Regulatory actions and communications

Data Analysis Requirements:

Trend analysis of post-market information

Pattern recognition for emerging risks

Risk-benefit evaluation updates

Effectiveness assessment of risk controls

Risk Management Updates

Triggers for Risk Management Review:

New hazard identification

Changes in risk occurrence rates

Severity assessment modifications

Risk control measure effectiveness issues

Update Process:

Re-evaluate risk analysis based on new data

Update risk control measures if needed

Revise benefit-risk analysis if applicable

Document changes in risk management file

Common Implementation Mistakes and How to Avoid Them

Mistake 1: Late Risk Management Implementation

Problem: Conducting risk management activities late in design process

Solution: Integrate risk management from initial design phases

Best Practice: Include risk management in design planning and all design reviews

Mistake 2: Inadequate Hazard Identification

Problem: Missing hazards due to limited analysis scope

Solution: Use systematic hazard identification methods

Best Practice: Involve multidisciplinary teams including clinicians, engineers, and regulatory experts

Mistake 3: Poor Risk Acceptability Criteria

Problem: Vague or inconsistent risk acceptability criteria

Solution: Establish clear, objective criteria based on device type and intended use

Best Practice: Benchmark against similar devices and regulatory expectations

Mistake 4: Insufficient Post-Market Activities

Problem: Treating risk management as one-time design activity

Solution: Implement continuous post-market surveillance system

Best Practice: Establish systematic data collection and analysis processes

Mistake 5: Inadequate Documentation

Problem: Incomplete or poorly organized risk management files

Solution: Maintain comprehensive, traceable documentation

Best Practice: Use standardized templates and document management systems

Risk Management Tools and Techniques

Hazard Identification Methods

Preliminary Hazard Analysis (PHA):

Early-stage hazard identification

High-level risk screening

Suitable for concept and design phases

Failure Mode and Effects Analysis (FMEA):

Systematic analysis of failure modes

Quantitative risk assessment capability

Excellent for design and process analysis

Fault Tree Analysis (FTA):

Top-down approach to hazard analysis

Useful for complex systems

Identifies combinations of failures

Hazard and Operability Study (HAZOP):

Systematic examination of process deviations

Effective for manufacturing process analysis

Identifies operational hazards

Risk Assessment Tools

Risk Matrices:

Simple probability vs. severity assessment

Visual risk level communication

Suitable for qualitative analysis

Monte Carlo Simulation:

Quantitative risk assessment

Handles uncertainty and variability

Useful for complex risk scenarios

Bow-Tie Analysis:

Combines fault tree and event tree analysis

Shows risk control measure effectiveness

Excellent for communication and training

Software as Medical Device (SaMD) Considerations

ISO 14971:2019 specifically addresses SaMD applications:

SaMD Risk Management Approach

Software-Specific Hazards:

Algorithm errors and computational failures

Data integrity and security issues

User interface and usability problems

Integration and interoperability risks

SaMD Risk Control Measures:

Software verification and validation

Cybersecurity and data protection

User training and competency requirements

Software maintenance and updates

Post-Market Surveillance for SaMD:

Software performance monitoring

User feedback and error reporting

Cybersecurity incident tracking

Algorithm performance validation

Integration with IEC 62304

Software Lifecycle Process Integration:

Risk management inputs to software planning

Hazard analysis during software design

Risk control through software architecture

Post-market surveillance of software performance

Global Regulatory Considerations

FDA Requirements

FDA Recognition of ISO 14971:

FDA-Specific Considerations:

Emphasis on clinical risk-benefit analysis

Post-market surveillance reporting requirements

Integration with FDA's MAUDE database

Alignment with FDA guidance documents

EU MDR/IVDR Requirements

Harmonized Standard Status:

EN ISO 14971:2019+A11:2021 is harmonized with MDR/IVDR

Annex ZA demonstrates MDR compliance

Annex ZB demonstrates IVDR compliance

Presumption of conformity with General Safety and Performance Requirements

EU-Specific Requirements:

Clinical evaluation and risk management integration

Post-market clinical follow-up obligations

Vigilance reporting and risk communication

Notified body assessment of risk management

Other Global Markets

Health Canada:

ISO 14971 required for medical device licenses

Integration with Quality System Certification

Post-market surveillance reporting

TGA (Australia):

Risk management requirements for TGA registration

Alignment with Australian regulatory framework

Post-market monitoring obligations

Advanced Risk Management Strategies

Digital Health and AI/ML Devices

Unique Risk Considerations:

Algorithm bias and fairness

Data privacy and security

Continuous learning system risks

Human-AI interaction challenges

Risk Control Approaches:

Algorithm validation and testing

Data governance and quality assurance

User interface design and training

Continuous monitoring and updates

Combination Products

Multi-Disciplinary Risk Management:

Drug-device interaction risks

Integrated manufacturing controls

Combined clinical risk assessment

Coordinated post-market surveillance

Cybersecurity Risk Management

Cybersecurity Risk Integration:

Threat modeling and vulnerability assessment

Security controls and monitoring

Incident response and recovery

Supply chain security management

Risk Management File Documentation

Required Documentation Components

Risk Management Plan:

Risk management policy and procedures

Risk acceptability criteria

Risk management activities and timelines

Competent personnel assignments

Risk Analysis Documentation:

Hazard identification records

Risk estimation methodologies

Risk evaluation results

Risk control measure specifications

Risk Control Verification:

Control measure effectiveness verification

Residual risk assessment results

Benefit-risk analysis (if applicable)

Risk management report

Post-Market Surveillance Records:

Post-market data collection procedures

Risk management review results

Risk management updates and changes

Effectiveness monitoring data

Documentation Best Practices

Traceability Requirements:

Link risks to specific device components

Trace control measures to risk analysis

Connect post-market data to risk updates

Maintain version control and change history

Review and Approval Process:

Independent review of risk management activities

Competent personnel approval requirements

Management review integration

Audit trail maintenance

Measuring Risk Management Effectiveness

Performance Indicators

Leading Indicators:

Hazard identification completeness

Risk assessment accuracy

Control measure implementation timeliness

Training effectiveness metrics

Lagging Indicators:

Post-market incident rates

Field corrective action frequency

Customer satisfaction scores

Regulatory inspection findings

Continuous Improvement

Risk Management System Review:

Annual risk management effectiveness assessment

Benchmarking against industry performance

Process improvement identification

Technology and method updates

Organizational Learning:

Cross-product risk management lessons

Industry best practice adoption

Regulatory expectation updates

Competency development programs

Strategic Implementation Recommendations

Organizational Readiness

Resource Requirements:

Dedicated risk management personnel

Cross-functional team involvement

Training and competency development

Technology and tool investments

Cultural Transformation:

Risk-aware decision making

Proactive hazard identification

Continuous improvement mindset

Regulatory compliance commitment

Phased Implementation Approach

Phase 1: Foundation Building (Months 1-3)

Establish risk management policy and procedures

Train personnel on ISO 14971 requirements

Set up risk management file structure

Begin pilot product risk analysis

Phase 2: System Implementation (Months 4-9)

Complete risk analysis for all products

Implement risk control measures

Establish post-market surveillance system

Conduct risk management reviews

Phase 3: Optimization and Maturity (Months 10-12)

Refine risk management processes

Implement advanced risk assessment tools

Establish continuous improvement programs

Achieve full regulatory compliance

Strategic Takeaways

ISO 14971:2019 represents a fundamental shift toward integrated, lifecycle-based risk management:

Start early - Risk management must begin in design planning phases

Think systematically - Use structured methods for hazard identification and risk assessment

Focus on post-market - Establish robust surveillance systems for continuous risk monitoring

Integrate deeply - Embed risk management throughout quality management systems

Document thoroughly - Maintain comprehensive, traceable risk management files

Improve continuously - Use post-market data to enhance risk management effectiveness

Effective risk management is not just about regulatory compliance—it's about building safer, more effective medical devices that improve patient outcomes while protecting organizations from regulatory and commercial risks.

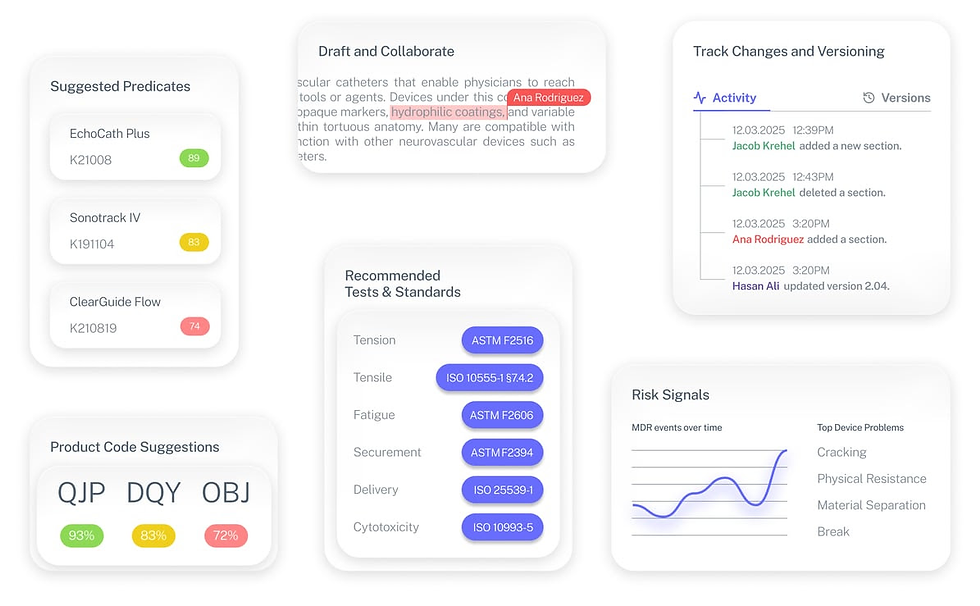

The Fastest Path to Market

No more guesswork. Move from research to a defendable FDA strategy, faster. Backed by FDA sources. Teams report 12 hours saved weekly.

FDA Product Code Finder, find your code in minutes.

510(k) Predicate Intelligence, see likely predicates with 510(k) links.

Risk and Recalls, scan MAUDE and recall patterns.

FDA Tests and Standards, map required tests from your code.

Regulatory Strategy Workspace, pull it into a defendable plan.

👉 Start free at complizen.ai

Frequently Asked Questions

Is ISO 14971 mandatory for medical devices?

While not legally required, ISO 14971 is effectively mandatory as major regulators worldwide recognize it as the standard for medical device risk management. Non-compliance significantly limits market access.

How does ISO 14971:2019 differ from the 2007 version?

Key differences include enhanced post-market surveillance requirements, benefit-risk analysis introduction, streamlined structure, and stronger integration with quality management systems.

What's the relationship between ISO 14971 and ISO 13485?

ISO 13485 requires risk management integration throughout the quality management system. ISO 14971 provides the specific methodology for medical device risk management.

How often should risk management activities be updated?

Risk management should be updated whenever new hazards are identified, risk control effectiveness changes, or significant post-market data becomes available. Regular reviews are recommended annually at minimum.

Can ISO 14971 be applied to software medical devices?

Yes, ISO 14971:2019 specifically addresses Software as Medical Device (SaMD) applications and should be integrated with IEC 62304 software lifecycle processes.