Medical Device Labeling Requirements: Complete FDA 21 CFR 801 Compliance Guide 2025

- Beng Ee Lim

- Aug 15, 2025

- 8 min read

Updated: Oct 17, 2025

FDA requires medical device labeling to include manufacturer information, intended use, adequate directions, warnings, UDI (where applicable), and device-specific requirements. Labeling encompasses all written materials including labels, packaging, instructions for use, and promotional materials. Compliance requires both content accuracy and quality system controls under 21 CFR 820.120.

This guide covers all FDA labeling requirements, common violations, and compliance strategies to prevent enforcement actions.

What FDA Considers "Medical Device Labeling"

The biggest mistake companies make is thinking labeling only refers to the physical label on their device. FDA defines medical device labeling much more broadly, encompassing virtually all written communications about your device.

FDA's Comprehensive Labeling Definition

Under 21 CFR Part 801, medical device labeling includes all labels and other written, printed, or graphic matter:

On or Accompanying the Device:

Physical device labels and stickers

Packaging and shipping containers

Instructions for use (IFU) and user manuals

Package inserts and product information sheets

Software interfaces and electronic displays

Promotional and Educational Materials:

Marketing brochures and sales literature

Website content and digital materials

Training materials and educational content

Technical specifications and white papers

Critical FDA Position: According to an appellate court decision: "Most, if not all advertising, is labeling. The term 'labeling' is defined in the FFDCA as including all printed matter accompanying any article."

The Business Impact of This Broad Definition

Compliance Scope: Every piece of written material about your device must comply with FDA labeling regulations, not just the physical product label.

Enforcement Risk: FDA routinely cites companies for labeling violations in promotional materials, websites, and training documents that contradict approved labeling.

Quality System Integration: All labeling materials must be controlled under your Quality Management System per 21 CFR 820.120.

Core FDA Labeling Requirements: 21 CFR Part 801

All medical devices distributed in the United States must comply with general labeling requirements under 21 CFR Part 801, regardless of classification or regulatory pathway.

Mandatory Label Content

Manufacturer Information (21 CFR 801.1): The label must contain the name and place of business of manufacturer, packer, or distributor including street address, city, state, and zip code. If the firm's street address is in the local telephone directory, the street address can be omitted.

Qualification Statements: If the firm listed on the label is not the manufacturer, the firm information must be qualified by an appropriate statement such as "Manufactured for..." or "Distributed by..."

Adequate Directions for Use (21 CFR 801.5)

FDA Definition: "Adequate directions for use" means directions under which the layman can use a device safely and for the purposes intended.

Required Content:

Statements of all purposes for which and conditions under which the device can be used

Quantity of dose for each use and usual quantities for persons of different ages and physical conditions

Frequency and duration of use

Time of administration or application

Route or method of administration or application

Any preparation necessary for use

Professional Use Exemption: Devices restricted to prescription use are exempt from adequate directions requirements when used by qualified practitioners.

Warnings and Contraindications

Mandatory Warning Statements:

All foreseeable risks and safety information

Contraindications for specific patient populations

Proper storage and handling instructions

Expiration date information where applicable

Format Requirements: Warnings must be prominently displayed and clearly distinguishable from other labeling content through font size, contrast, or positioning.

Unique Device Identification (UDI) Requirements

The UDI system under 21 CFR Part 801 Subpart B and 21 CFR Part 830 represents one of FDA's most significant labeling requirements, affecting most medical devices.

UDI Compliance Requirements

General Rule (21 CFR 801.20): The label of every medical device and package shall bear a unique device identifier (UDI) that meets the requirements of this subpart and part 830 of this chapter.

UDI Components:

Device Identifier (DI): Mandatory, fixed portion identifying the specific version/model and labeler

Production Identifier (PI): Conditional, variable portion identifying lot number, serial number, expiration date, and/or manufacturing date

UDI Exemptions

Devices Exempt from UDI Requirements:

Class I devices exempt from Good Manufacturing Practice requirements (21 CFR Part 820), except recordkeeping and complaint files

Custom devices within the meaning of 21 CFR 812.3(b)

Investigational devices under Part 812

Devices intended for export from the United States

Devices used solely for research, teaching, or chemical analysis

Pre-compliance inventory

Individual single-use items within a multi-pack (package still needs UDI)

Veterinary-only devices

Combo products/conv. kits nuances

Shipping containers

Class I UDI needn’t include PI

Compliance Timeline: UDI requirements are phased by device class with specific compliance dates. Devices manufactured and labeled prior to compliance dates have a 3-year grace period.

GUDID Database Submission

Global Unique Device Identification Database (GUDID): Device labelers must submit device information to FDA's GUDID database, including device description, intended use, and labeling information.

Submission Requirements:

Submit before first commercial distribution

Update within 60 days of any changes

Maintain accurate device status information

Quality System Labeling Controls: 21 CFR 820.120

FDA requires comprehensive quality system controls for all labeling activities under the Quality System Regulation.

Labeling Control Requirements

Control Procedure (21 CFR 820.120): Each manufacturer must establish and maintain procedures to control labeling activities, ensuring correct labeling is issued and used for each device.

Five Critical Control Areas:

1. Labeling Integrity:

Labels must remain affixed to the device throughout distribution and use

Labeling must remain legible under customary conditions of processing, storage, handling, distribution, and use

Specifications must address substrate, dimensions, ink, finish, and mounting methods

2. Labeling Storage:

Implement systems ensuring correct labels are applied to corresponding devices

Prevent mix-ups through proper storage and identification procedures

Control access to labeling materials and storage areas

3. Labeling Inspection:

Inspect incoming labeling materials per 21 CFR 820.80(b)

Verify labeling accuracy and quality before use

Document inspection results and corrective actions

4. Labeling Operations:

Control labeling application processes

Train personnel on proper labeling procedures

Implement verification checks during labeling operations

5. Labeling Documentation:

Maintain device master records including labeling specifications

Document labeling changes and approvals

Ensure traceability from design inputs to final labeling

Common Quality System Labeling Violations

FDA 483 Observations:

Inadequate labeling control procedures

Label mix-ups due to improper storage

Missing or incorrect labeling inspections

Insufficient documentation of labeling changes

Lack of training on labeling procedures

Device-Specific Labeling Requirements

Beyond general requirements, many devices have additional labeling obligations based on classification, intended use, or regulatory pathway.

Prescription Device Labeling

Rx-Only Statement: Prescription devices must include "Caution: Federal law restricts this device to sale by or on the order of a physician" or equivalent statement.

Professional Labeling:

Detailed instructions for healthcare providers

Clinical performance data

Contraindications and warnings

Adverse event information

Over-the-Counter (OTC) Device Labeling

Consumer-Friendly Instructions:

Simple, clear directions for lay users

Step-by-step usage instructions

Safety warnings in plain language

Storage and maintenance information

Sterile Device Labeling

Sterility Information:

Sterilization method identification

Sterile barrier system integrity indicators

Storage conditions maintaining sterility

Single-use designations where applicable

Software and Digital Device Labeling

Electronic Labeling Provisions: FDA allows electronic labeling for prescription devices used in healthcare facilities under specific conditions, reducing paper-based labeling requirements.

Software Interface Requirements:

User interface elements providing instructions, warnings, or device identification

Software version identification

Symbol Usage in Medical Device Labeling

FDA regulations under 21 CFR 801.15 govern the use of symbols in medical device labeling, balancing international harmonization with safety requirements.

Stand-Alone Symbol Requirements

2016 Final Rule Changes: FDA now allows stand-alone symbols (without adjacent explanatory text) if certain requirements are met:

Acceptable Symbol Standards:

Symbols established in standards developed by recognized Standards Development Organizations (SDOs)

FDA has recognized the standard or portion containing the symbol

Symbol is used according to FDA recognition specifications

Required Information: Provide a symbols glossary in the labeling (paper or electronic) and place a prominent statement on/in the package identifying the glossary’s location.

Common Medical Device Symbols

Internationally Recognized Symbols:

Sterilization method indicators

Temperature and storage condition symbols

Single-use and reusable device indicators

Manufacturer and date of manufacture symbols

Language and Translation Requirements

FDA has specific requirements for foreign language labeling and translation accuracy.

English Language Requirements

General Rule (21 CFR 801.15): All labeling shall be in English, except for products distributed solely within Puerto Rico or U.S. territories where the predominant language is other than English.

Foreign Language Additions: If any representation on the device label or labeling appears in a foreign language, then all required labeling shall also appear in that foreign language. For Rx-only devices sold solely in Puerto Rico, Spanish-only labeling is allowed.

Translation Accuracy Standards

FDA Expectations:

Accurate translation of all required elements

Cultural appropriateness for target populations

Consistency across all labeling materials

Regular review and updates of translated content

Regulatory Submission Labeling Requirements

Labeling plays a critical role in FDA regulatory submissions and must be properly prepared for review.

510(k) Submission Labeling

Required Elements:

Draft labels meeting all applicable requirements

Instructions for use demonstrating safe and effective use

Promotional materials and advertising claims

Comparison to predicate device labeling

FDA Review Focus:

Consistency with intended use and indications

Adequacy of warnings and contraindications

Compliance with general and specific labeling requirements

Support for substantial equivalence claims

PMA Submission Labeling

Comprehensive Labeling Package:

Complete labeling including all patient and provider materials

Clinical data supporting labeling claims

Risk-benefit analysis reflected in labeling

Post-market study commitments

Labeling Changes Post-Approval

Change Control Requirements: For 510(k) devices, apply Deciding When to Submit a 510(k) for a Change to an Existing Device (see Labeling Changes flowchart). For PMA devices, see 814.39 to determine supplement type.

Significant Changes Requiring New Submission:

New indications for use

New patient populations

Significant safety warnings

Major use instruction modifications

Common Labeling Violations and How to Avoid Them

Top FDA 483 Labeling Citations

Label Mix-ups and Storage Issues:

Implementing inadequate labeling storage systems

Failing to prevent similar labels from being confused

Insufficient access controls to labeling areas

Prevention Strategy:

Color-coding systems for different product lines

Barcode verification for label application

Segregated storage with clear identification

Regular audits of labeling storage areas

Missing Required Information:

Omitting UDI when required

Incorrect or missing manufacturer information

Inadequate directions for use

Missing expiration dates or lot numbers

Prevention Strategy:

Comprehensive labeling checklists for each device

Multiple review stages before labeling approval

Regular training on labeling requirements

Automated systems for required information inclusion

Promotional Material Violations

Off-Label Claims:

Promoting uses not included in FDA clearance/approval

Making unsubstantiated performance claims

Comparing to devices outside approved indications

Prevention Strategy:

Legal and regulatory review of all promotional materials

Clear procedures for sales team training

Regular monitoring of marketing communications

Documentation of approved promotional claims

Inconsistent Information:

Contradictions between different labeling materials

Website content conflicting with approved labeling

Training materials containing unapproved information

Prevention Strategy:

Single source of truth for all labeling content

Version control systems for labeling materials

Regular updates across all platforms and materials

Cross-functional review processes

Implementation Best Practices

Labeling Development Process

Phase 1: Requirements Analysis

Identify all applicable FDA requirements

Determine device-specific labeling needs

Analyze user requirements and use environments

Review predicate device labeling (for 510(k) devices)

Phase 2: Content Development

Create comprehensive labeling content

Ensure consistency across all materials

Include required warnings and contraindications

Develop user-friendly instructions

Phase 3: Review and Approval

Internal cross-functional review

Legal and regulatory approval

Clinical review for accuracy

Final management approval

Phase 4: Quality System Integration

Implement labeling control procedures

Train personnel on labeling requirements

Establish change control processes

Create documentation systems

Global Labeling Strategy

Harmonization Opportunities:

Leverage international symbol standards

Align with global regulatory requirements where possible

Consider translation requirements early in development

Plan for multiple market labeling needs

Regional Considerations:

EU MDR labeling requirements for European markets

Health Canada specific labeling needs

Other international market requirements

Cultural and linguistic considerations

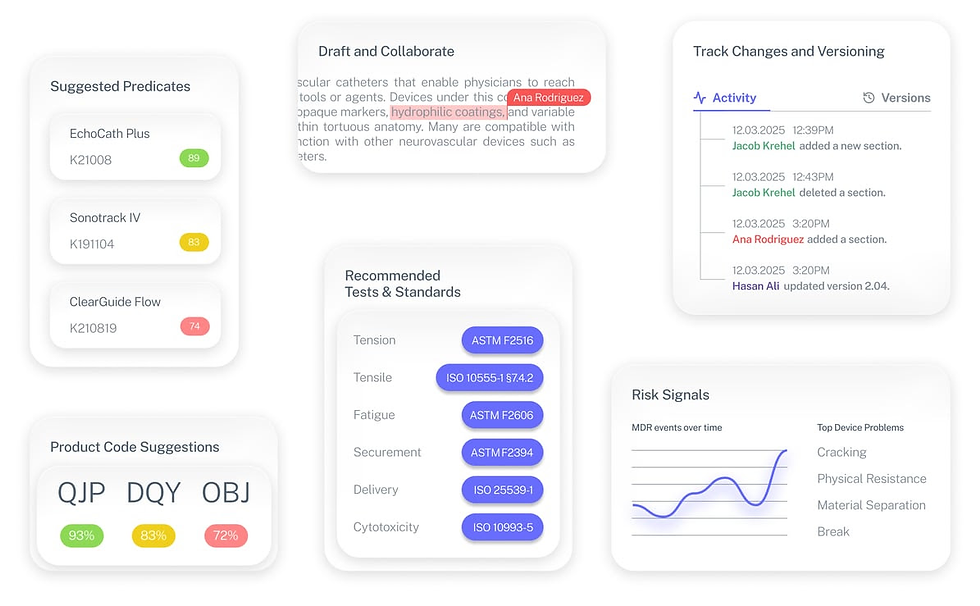

The Fastest Path to Market

No more guesswork. Move from research to a defendable FDA strategy, faster. Backed by FDA sources. Teams report 12 hours saved weekly.

FDA Product Code Finder, find your code in minutes.

510(k) Predicate Intelligence, see likely predicates with 510(k) links.

Risk and Recalls, scan MAUDE and recall patterns.

FDA Tests and Standards, map required tests from your code.

Regulatory Strategy Workspace, pull it into a defendable plan.

👉 Start free at complizen.ai

Frequently Asked Questions

Do I need UDI on my Class I device?

Most Class I devices exempt from GMP requirements under 21 CFR Part 820 don't require UDI. However, check the specific exemption list as some Class I devices do require UDI.

Can I use electronic labeling instead of paper instructions?

FDA allows electronic labeling for prescription devices used in healthcare facilities under specific conditions outlined in guidance documents. OTC devices generally require paper labeling.

What labeling changes require a new 510(k)?

Significant labeling changes affecting safety, effectiveness, or intended use typically require new 510(k) submissions. Minor corrections or clarifications may not require new submissions.

How do I handle labeling for combination products?

Combination products have complex labeling requirements depending on the lead center assignment. Early FDA interaction through pre-submission meetings is recommended.

What are the penalties for labeling violations?

Penalties range from FDA 483 observations and warning letters to product recalls, consent decrees, and criminal prosecution for willful violations.