What Is a Design History File (DHF)? Complete 2025 Guide

- Beng Ee Lim

- Sep 22, 2025

- 6 min read

Updated: Oct 17, 2025

A Design History File (DHF) is a mandatory compilation of records documenting how a medical device was designed and developed according to FDA requirements under 21 CFR Part 820.30. The DHF demonstrates that design controls were followed throughout development and serves as primary evidence during FDA audits and regulatory submissions.

This guide covers DHF requirements, contents, creation process, and compliance strategies to help you build audit-ready documentation.

What Is a Design History File?

A Design History File (DHF) is the structured record that shows your medical device was developed under FDA design controls. Under 21 CFR §820.30(j), manufacturers must maintain a DHF for each type of device, documenting (or referencing) the evidence that design and development followed the approved plan and the QSR’s design-control requirements—e.g., design reviews, verification, validation (including risk analysis), and design changes.

Regulatory origin. The Safe Medical Devices Act of 1990 (SMDA) gave FDA the authority to add design controls; FDA did so in the 1996 Quality System Regulation (QSR), effective June 1, 1997.

Who must keep a DHF? Design controls—and therefore the DHF—apply to Class II and Class III devices and specific Class I devices listed in §820.30(a)(2).

Heads-up (future): FDA’s QMSR (aligned to ISO 13485) becomes effective Feb 2, 2026. Expect the design-and-development file concept to continue under the updated rule.

Why the DHF Matters for Medical Device Companies

Regulatory Compliance

During a QSIT inspection, FDA investigators routinely review the DHF as part of the Design Controls subsystem to confirm conformity with §820.30

(planning → inputs/outputs → reviews → verification → validation (incl. risk) → transfer → changes).

Market Access Requirements

Risk Management

The DHF provides end-to-end traceability from user needs to final design, including risk analysis (required in §820.30(g) and documented in the DHF), supporting safe design decisions and effective mitigations.

Knowledge Preservation

A complete DHF captures rationale, decisions, and evidence. That tribal knowledge speeds design changes, supports complaint/CAPA investigations, and streamlines next-gen development.

DHF vs. DMR vs. DHR: Understanding the Differences

The medical device industry uses three similar acronyms that often cause confusion. Understanding their distinct purposes is essential for proper documentation:

Document | Purpose | Focus | When Created |

DHF (Design History File) | Documents design development process | Why the device was designed this way | During design phase |

DMR (Device Master Record) | Manufacturing instructions and specifications | How to build the device | After design completion |

DHR (Device History Record) | Production history of specific units | Proof device was built per DMR | During manufacturing |

Simple Memory Aid:

DHF = Design history (development process)

DMR = Device master (manufacturing recipe)

DHR = Device history (production records)

Think DHF → DMR → DHR (design → recipe → proof).

What Must Be Included in a DHF

The DHF must contain or reference all records demonstrating design control compliance. According to 21 CFR Part 820.30, required documentation includes:

Design and Development Planning

Design plans outlining development activities, responsibilities, and timelines

Resource allocation and interdepartmental coordination plans

Design review schedules and milestone definitions

Design Input Documentation

User needs and intended use specifications

Performance requirements and acceptance criteria

Regulatory and standards requirements

Design input approval records

Design Output Documentation

Device specifications, drawings, and component details

Software specifications and architecture documents

Manufacturing and testing specifications

Design output approval records

Design Review Records

Review meeting minutes and participant lists

Design review results and action items

Cross-functional team evaluations

Independent review documentation

Design Verification Documentation

Test protocols and procedures

Verification test results and analysis

Traceability between inputs and outputs

Statistical analysis and acceptance criteria

Design Validation Records

Validation protocols under actual use conditions

Clinical data and user feedback

Risk analysis and mitigation strategies

Final validation reports and approvals

Design Transfer Documentation

Manufacturing process specifications

Production procedures and work instructions

Quality control and acceptance criteria

Transfer approval and signoff records

Design Change Documentation

Change control procedures and approvals

Impact assessments and risk analysis

Updated specifications and test results

Change implementation records

DHF Creation Process: Step-by-Step

Step 1: Establish DHF Structure

Create a centralized system for organizing design documentation. Whether physical or digital, the DHF must provide clear traceability and easy access for auditors.

Step 2: Document Design Planning

Begin with comprehensive design plans that outline your development approach, timelines, and responsibilities. Include risk management planning and regulatory strategy.

Step 3: Capture Design Inputs

Document all requirements driving your design decisions. Include user needs, performance specifications, regulatory requirements, and safety considerations.

Step 4: Record Design Outputs

Document all design results including specifications, drawings, test procedures, and manufacturing instructions. Ensure outputs are traceable to corresponding inputs.

Step 5: Conduct and Document Design Reviews

Hold formal reviews at appropriate design phases. Document participants, design versions reviewed, results, and any required actions.

Step 6: Perform and Document Verification

Execute verification activities to confirm design outputs meet inputs. Document methods, results, and acceptance decisions.

Step 7: Complete Design Validation

Validate the design under actual use conditions. Document that the device meets user needs and intended uses as specified in design inputs.

Step 8: Document Design Transfer

Record the transfer of design outputs to manufacturing. Include production procedures, quality controls, and acceptance criteria.

Step 9: Maintain Change Controls

Implement procedures for managing design changes throughout the product lifecycle. Document all changes, approvals, and impact assessments.

Common DHF Mistakes That Trigger FDA Issues

Late DHF Assembly

Creating the DHF after development completion leads to incomplete documentation and missing traceability. Build the DHF continuously throughout development.

Poor Organization

Disorganized files with missing documents or unclear references frustrate auditors and suggest poor design controls. Implement systematic organization from project start.

Incomplete Documentation

Missing verification results, unsigned approvals, or undocumented design changes indicate insufficient design controls. Ensure all required elements are documented and approved.

Weak Traceability

Inability to trace design outputs back to inputs suggests inadequate design controls. Implement clear traceability matrices linking requirements to specifications.

Inadequate Change Control

Undocumented or poorly controlled design changes raise quality concerns. Establish formal change control procedures and maintain complete change records.

Missing Risk Management

Insufficient risk analysis documentation fails to demonstrate safety considerations. Integrate risk management throughout design and document all activities.

DHF in the Context of ISO 13485 and International Markets

While FDA requires a Design History File, ISO 13485:2016 uses slightly different terminology. Clause 7.3.10 requires a "design and development file" that serves the same purpose as the DHF.

ISO 13485 Requirements: The design and development file must include or reference records demonstrating conformity to design and development requirements, including records of design changes.

Global Harmonization: Many companies maintain DHF documentation that satisfies both FDA and ISO requirements, enabling access to multiple markets with unified documentation.

Digital DHF Management Best Practices

Centralized Document Control

Implement electronic Quality Management Systems (eQMS) that provide centralized document storage, version control, and automated workflows for approvals and changes.

Real-Time Compilation

Use systems that automatically compile DHF documentation as design activities progress, rather than assembling files retrospectively.

Automated Traceability

Deploy tools that automatically maintain traceability between design inputs, outputs, verification results, and validation activities.

Audit Readiness

Maintain DHF documentation in formats that enable rapid response to FDA information requests and audit preparation.

DHF and Regulatory Submissions

DHF documentation supports substantial equivalence demonstrations by providing design rationale, testing data, and comparative analysis with predicate devices.

Comprehensive DHF records are essential for PMA submissions, providing detailed design history and safety/effectiveness evidence required for approval.

DHF documentation supports De Novo requests by demonstrating controlled design processes and risk mitigation strategies for novel devices.

2026 QMSR Changes: What You Need to Know

FDA's new Quality Management System Regulation (QMSR), effective February 2026, aligns US requirements with ISO 13485:2016. Under QMSR, the terms DHF, DMR, and DHR will be replaced by the broader concept of "Medical Device File" (MDF).

Important Note: While terminology changes, documentation requirements remain essentially the same. Companies can continue using DHF internally while meeting QMSR requirements.

Preparation Strategy:

Review current DHF practices against ISO 13485 requirements

Ensure documentation covers all design and development activities

Maintain traceability and change control procedures

Plan transition to MDF terminology if desired

The Fastest Path to Market

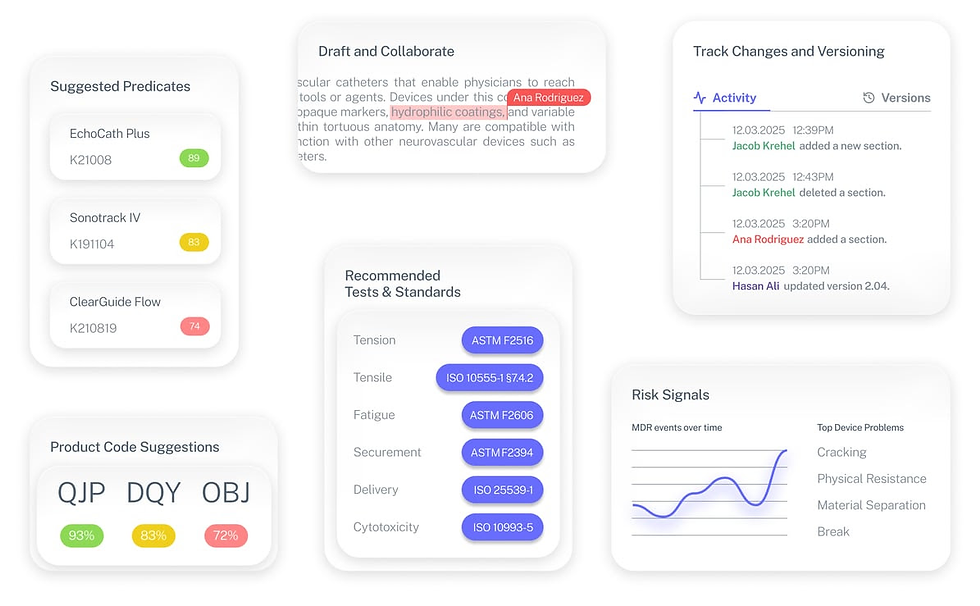

No more guesswork. Move from research to a defendable FDA strategy, faster. Backed by FDA sources. Teams report 12 hours saved weekly.

FDA Product Code Finder, find your code in minutes.

510(k) Predicate Intelligence, see likely predicates with 510(k) links.

Risk and Recalls, scan MAUDE and recall patterns.

FDA Tests and Standards, map required tests from your code.

Regulatory Strategy Workspace, pull it into a defendable plan.

👉 Start free at complizen.ai

Frequently Asked Questions

Do I need a separate DHF for each device model?

You need a DHF for each "type" of device. Similar devices with identical designs can share a DHF, but different designs require separate files.

Can the DHF reference documents stored elsewhere?

Yes, the DHF can reference documents rather than containing them physically. Ensure referenced documents are easily accessible and properly controlled.

How long must I maintain DHF records?

DHF records must be maintained for the lifetime of the device type plus additional time as specified in your document control procedures.

What happens if my DHF is incomplete during an audit?

Incomplete DHF documentation can result in FDA observations, warning letters, or regulatory delays. Ensure comprehensive documentation before regulatory interactions.

How does the DHF relate to design controls?

The DHF is the documented output of your design controls process, proving that you followed systematic design procedures throughout development.

Can I use software to manage my DHF?

Yes, electronic DHF management through eQMS platforms is widely accepted and often preferred for organization, traceability, and audit preparation.