Predetermined Change Control Plan (PCCP) for AI/ML-Enabled Devices: 2025 FDA Guide

- Beng Ee Lim

- Aug 6, 2025

- 10 min read

Updated: Sep 7, 2025

A Predetermined Change Control Plan (PCCP) is FDA documentation that lets you pre-define specific AI/ML software changes—and the methods to develop, validate, implement, and monitor them—so those updates can be made without a new marketing submission, when executed exactly as an authorized PCCP. PCCPs include three components: Description of Modifications, Modification Protocol, and Impact Assessment. Available for 510(k), De Novo, and PMA pathways for AI-enabled device software functions.

This guide covers the final December 2024 FDA guidance requirements, implementation strategies, and practical examples for successful PCCP development.

What Is a Predetermined Change Control Plan (PCCP)?

A Predetermined Change Control Plan is a regulatory framework that allows manufacturers to implement pre-approved modifications to AI-enabled medical devices without submitting supplemental marketing applications for each change. This approach addresses the iterative nature of AI/ML development while maintaining safety and effectiveness standards.

Why PCCPs Are Essential for AI Medical Devices

Traditional Change Control Limitations: Conventional medical device change control requires new submissions (Special 510(k), PMA supplement) for significant software modifications. For AI devices that continuously learn and improve, this creates regulatory bottlenecks that can delay critical updates.

PCCP Strategic Advantages:

Continuous Innovation: Implement AI improvements without regulatory delays

Cost Reduction: Eliminate expensive supplemental submission cycles

Competitive Edge: Deploy algorithmic enhancements faster than competitors

Patient Benefit: Accelerate delivery of improved diagnostic accuracy and treatment outcomes

FDA Regulatory Authority

The FDA's PCCP authority stems from the Food and Drug Omnibus Reform Act (FDORA) of 2022, which added section 515C to the Federal Food, Drug, and Cosmetic Act. This provides express statutory authority for FDA to authorize predetermined change control plans as part of initial marketing submissions.

AI-DSF Definition and Scope

Updated FDA Terminology (2025)

The final FDA guidance transitioned from "Machine Learning-Enabled Device Software Functions (ML-DSF)" to "Artificial Intelligence-Enabled Device Software Functions (AI-DSF)" to reflect broader AI application scope.

FDA AI Definition: "A machine-based system that can, for a given set of human-defined objectives, make predictions, recommendations, or decisions influencing real or virtual environments."

AI-DSF Definition: "A device software function that implements an AI model" and includes various AI techniques beyond just machine learning algorithms.

PCCP Applicability

Devices Eligible for PCCP:

AI-enabled medical devices across all risk classifications

Device-led combination products with AI-DSF components

Software as Medical Device (SaMD) with AI functionality

Traditional medical devices with embedded AI algorithms

Regulatory Pathways:

510(k) Premarket Notification: Most common pathway for AI device modifications

De Novo Classification Request: Novel AI devices establishing new device classifications

PMA Applications: High-risk AI devices requiring comprehensive safety and effectiveness data

Exclusions:

Minor software maintenance that doesn't affect safety or effectiveness (covered under Quality System Regulation)

Changes to drug or biologic components of combination products

Modifications outside the original device intended use without specific justification

Three Essential PCCP Components

Component 1: Description of Modifications

This section specifies exactly what changes will occur to the AI-DSF and their expected impact on device performance.

Required Elements:

Specific Modification Types:

Algorithm parameter adjustments and threshold modifications

Training data updates and model retraining procedures

Performance metric improvements (sensitivity, specificity, accuracy)

User interface enhancements that affect AI functionality

Integration updates for interoperable system compatibility

Device Characteristic Changes:

Quantified performance improvements with statistical bounds

Changes to device outputs, alerts, or recommendations

Modifications to data input requirements or processing methods

Updates to risk mitigation measures or safety controls

Implementation Approach:

Automatic updates through software deployment systems

Manual updates requiring healthcare provider intervention

Hybrid approaches with user confirmation requirements

Rollback procedures for unsuccessful modifications

Example Description: "The AI-DSF will implement algorithm parameter adjustments to improve diagnostic accuracy for detecting diabetic retinopathy in retinal images. Modifications include sensitivity threshold adjustments (±5%), specificity optimization (target >95%), and integration of additional training data representing diverse patient populations. Updates will be deployed automatically with healthcare provider notification and 30-day performance monitoring period."

Component 2: Modification Protocol

This section details the systematic approach for developing, validating, and implementing the planned modifications.

Development Methodology:

Data Management Procedures:

Training data collection and validation protocols

Data quality assessment and bias evaluation methods

Dataset versioning and change documentation procedures

Performance monitoring data collection and analysis plans

Validation and Testing Requirements:

Pre-deployment testing protocols with acceptance criteria

Clinical validation methods for performance verification

Real-world performance monitoring and assessment procedures

Failure detection and response mechanisms

Implementation Controls:

Change authorization and approval workflows

Deployment scheduling and rollout procedures

User notification and training requirements

Documentation and audit trail maintenance

Quality Assurance Integration:

Integration with existing Quality Management System (QMS)

Design control procedures for modification management

Risk management updates and assessment protocols

Corrective and Preventive Action (CAPA) procedures for modification failures

Example Protocol: "Algorithm modifications will be validated using a holdout test dataset of 10,000 retinal images with confirmed diagnoses. Performance criteria require sensitivity ≥90% and specificity ≥95% with 95% confidence intervals. Successful validation triggers automated deployment with real-time performance monitoring for 30 days. Any performance degradation >5% triggers automatic rollback to previous algorithm version."

Component 3: Impact Assessment

This section evaluates the potential effects of planned modifications on device safety, effectiveness, and benefit-risk profile.

Safety Impact Analysis:

Patient Safety Considerations:

Potential for false positive/negative results and clinical consequences

Changes to diagnostic accuracy and treatment decision impact

Risk mitigation measures for modification failures

User training requirements for modified device functionality

Clinical Effectiveness Assessment:

Expected improvements to patient outcomes and diagnostic accuracy

Quantified performance metrics with statistical confidence intervals

Clinical workflow integration and healthcare provider impact

Long-term monitoring and assessment procedures

Risk-Benefit Analysis:

Detailed risk assessment using ISO 14971 methodology

Benefit quantification with clinical outcome improvements

Risk mitigation strategies and control measures

Post-market surveillance and monitoring plans

Stakeholder Impact:

Healthcare provider training and workflow modification requirements

Patient communication about device updates and performance changes

Integration impact on healthcare IT systems and interoperability

Regulatory reporting and notification procedures

Example Assessment: "Algorithm improvements are expected to reduce false negative rates by 15%, potentially preventing 150 missed diagnoses per 10,000 screenings. Clinical benefits include earlier diabetic retinopathy detection and treatment initiation. Risks include temporary performance variation during algorithm transition, mitigated by 30-day parallel monitoring and immediate rollback capability. Healthcare providers will receive automated performance reports and modification notifications."

PCCP Development Strategy

Pre-Development Planning

Device Classification Analysis: Determine appropriate regulatory pathway based on device risk classification and AI-DSF complexity. Higher-risk devices require more comprehensive PCCP documentation and validation protocols.

Intended Use Boundary Definition: Clearly establish the scope of modifications that remain within original device intended use. Any changes that might affect indications for use require careful justification and additional regulatory consideration.

Stakeholder Engagement:

FDA Pre-Submission Meetings: Discuss PCCP strategy and obtain agency feedback

Clinical Partners: Validate modification protocols with end-users

IT Integration Teams: Ensure compatibility with healthcare system requirements

Technical Implementation

AI Model Architecture Considerations:

Modular design enabling component-level modifications

Version control systems for algorithm and training data management

Performance monitoring integration and automated testing capabilities

Rollback mechanisms for unsuccessful modifications

Data Infrastructure Requirements:

Secure data collection and storage systems for ongoing training

Performance monitoring and analytics platforms

Real-world evidence collection and analysis capabilities

Integration with existing healthcare IT systems

Quality System Integration:

Design control procedures for PCCP-covered modifications

Risk management file updates and maintenance procedures

Document control and change management protocols

Training and competency management for development teams

Regulatory Submission Preparation

Documentation Organization: Structure PCCP documentation as standalone section within marketing submission, clearly cross-referenced with device description, risk analysis, and clinical evaluation sections.

Evidence Package Development:

Historical performance data demonstrating algorithm reliability

Validation study results supporting modification protocols

Risk analysis documentation with mitigation strategies

Clinical evidence supporting expected performance improvements

FDA Interaction Strategy:

Schedule Q-Submission meetings to validate PCCP approach

Prepare responses to anticipated FDA questions about modification scope

Develop communication plan for post-market performance reporting

Establish ongoing dialogue channels for PCCP implementation updates

Common PCCP Mistakes and How to Avoid Them

Scope and Boundary Errors

Mistake: Overly broad modification descriptions that exceed intended use boundaries

Impact: FDA rejection or requests for additional clinical data

Solution: Clearly define specific, bounded modifications with quantified performance parameters

Mistake: Insufficient justification for modifications that approach indications for use changes

Impact: Regulatory delays and additional submission requirements

Solution: Provide comprehensive rationale with clinical evidence supporting safety within current intended use

Technical Implementation Failures

Mistake: Inadequate validation protocols that don't demonstrate modification effectiveness

Impact: FDA questions about modification safety and effectiveness assurance

Solution: Develop rigorous testing protocols with statistical validation and acceptance criteria

Mistake: Missing rollback procedures for unsuccessful modifications

Impact: Patient safety concerns and regulatory compliance issues

Solution: Implement automated rollback systems with performance monitoring triggers

Documentation and Process Errors

Mistake: Inconsistency between PCCP components and other submission sections

Impact: FDA confusion and additional information requests

Solution: Ensure alignment between PCCP, device description, risk analysis, and clinical evaluation

Mistake: Insufficient integration with Quality Management System procedures

Impact: Post-market compliance challenges and audit findings

Solution: Integrate PCCP procedures with existing QMS design controls and change management

Strategic Implementation by Regulatory Pathway

510(k) Submission Strategy

Substantial Equivalence Considerations:

Demonstrate that PCCP modifications maintain substantial equivalence to predicate device

Reference predicate device performance characteristics in modification boundaries

Address any performance improvements that might affect equivalence determination

Predicate Device Analysis:

Identify predicate devices with similar AI functionality and modification approaches

Compare PCCP scope with predicate device capabilities and performance

Document how modifications maintain or improve upon predicate device performance

Documentation Focus:

Emphasize modification protocol validation and testing procedures

Demonstrate robust performance monitoring and quality controls

Reference FDA consensus standards for AI device development where applicable

De Novo Request Integration

Special Controls Development:

Incorporate PCCP requirements into proposed special controls framework

Demonstrate how modification protocols support novel device classification

Establish precedent for future 510(k) submissions referencing PCCP approach

Risk-Benefit Framework:

Comprehensive risk analysis addressing novel AI device functionality

Benefit quantification with clinical evidence supporting PCCP approach

Post-market study commitments for long-term modification effectiveness assessment

Innovation Pathway Benefits:

Position PCCP as enabling technology for continuous AI device improvement

Demonstrate regulatory pathway efficiency for AI device modifications

Establish framework for similar devices in device classification

PMA Application Enhancement

Clinical Evidence Integration:

Incorporate PCCP validation data into comprehensive clinical evaluation

Design clinical studies to support modification protocol validation

Include post-market study protocols for ongoing PCCP effectiveness assessment

Manufacturing and Quality:

Demonstrate PCCP integration with manufacturing quality systems

Address scale-up considerations for modification deployment procedures

Include post-market surveillance protocols specific to PCCP modifications

Post-Market Commitments:

Establish ongoing performance monitoring and reporting requirements

Commit to regular PCCP effectiveness assessment and FDA communication

Include modification failure analysis and corrective action protocols

Post-Market Implementation

Performance Monitoring Requirements

Real-World Evidence Collection:

Continuous performance monitoring with statistical process control

Real-world effectiveness assessment compared to pre-market validation

Adverse event monitoring specific to AI-DSF modifications

User feedback collection and analysis procedures

Reporting and Communication:

Regular performance reports to FDA with modification effectiveness data

Healthcare provider communication about device updates and performance changes

Patient notification procedures for significant modification deployments

Integration with existing medical device reporting (MDR) requirements

Quality System Maintenance

Ongoing PCCP Compliance:

Regular assessment of modification protocol effectiveness

Update procedures for PCCP scope or methodology changes

Integration with corrective and preventive action (CAPA) procedures

Training and competency maintenance for PCCP implementation teams

Change Control Integration:

Coordination between PCCP modifications and traditional change control

Assessment of modifications that might exceed PCCP scope

Documentation and approval procedures for PCCP boundary modifications

Risk management file updates for implemented modifications

Continuous Improvement

PCCP Evolution:

Assessment of modification protocol effectiveness and optimization opportunities

Integration of lessons learned from modification deployments

Expansion of PCCP scope based on real-world experience and regulatory feedback

Coordination with FDA on PCCP updates and improvements

Industry Best Practices:

Participation in industry working groups on AI device modification protocols

Sharing of lessons learned and best practices with regulatory community

Contribution to standards development for AI device lifecycle management

Collaboration on real-world evidence collection and analysis methods

International Considerations

Global Regulatory Alignment

International Harmonization: FDA collaborates with Health Canada and UK MHRA on PCCP guiding principles, promoting international alignment for AI device modification management.

EU AI Act Compliance: Consider European AI Act requirements for high-risk AI systems, including conformity assessment procedures and post-market monitoring obligations.

ISO Standards Integration:

ISO/IEC 23053: Framework for AI risk management

ISO/IEC 23894: AI risk management for AI systems

IEC 62304: Medical device software lifecycle processes with AI considerations

Multi-Market Strategy

Coordinated Submission Planning:

Develop PCCPs that address multiple regulatory jurisdiction requirements

Plan modification protocols that support global device deployment

Coordinate with international regulatory bodies on PCCP acceptance and implementation

Regional Adaptation:

Modify PCCP components to address specific regional regulatory requirements

Include local clinical evidence and validation data where required

Address cultural and healthcare system differences in modification deployment

Future Trends and Considerations

Regulatory Evolution

Expanded PCCP Scope: FDA considering expansion of PCCP framework beyond AI devices to other software-intensive medical devices requiring frequent updates.

Enhanced Automation: Development of automated PCCP assessment and approval procedures using regulatory science and AI tools for submission review.

Real-World Evidence Integration: Increased emphasis on real-world evidence collection and analysis to support PCCP modification effectiveness and safety assessment.

Technology Integration

Advanced AI Techniques:

Federated learning implementations with distributed model training

Continuous learning systems with automated performance optimization

Explainable AI requirements for modification transparency and validation

Interoperability Standards:

FHIR integration for AI device data exchange and modification coordination

HL7 standards for AI device modification notification and reporting

Cloud-based modification deployment and management systems

Implementation Checklist

Pre-Submission Phase

Strategic Planning:

Assess device eligibility for PCCP framework

Define modification scope and boundaries within intended use

Identify regulatory pathway and submission strategy

Schedule FDA pre-submission meeting to discuss PCCP approach

Technical Preparation:

Design AI architecture to support planned modifications

Develop validation protocols with statistical acceptance criteria

Implement performance monitoring and rollback systems

Integrate PCCP procedures with quality management system

PCCP Development

Documentation Preparation:

Complete Description of Modifications with quantified parameters

Develop comprehensive Modification Protocol with validation procedures

Conduct thorough Impact Assessment with risk-benefit analysis

Ensure consistency across all PCCP components and submission sections

Validation and Testing:

Execute modification protocol validation studies

Demonstrate rollback and failure response procedures

Validate performance monitoring and assessment systems

Complete integration testing with existing device functionality

Post-Submission Management

FDA Interaction:

Respond to FDA questions with supporting evidence and clarification

Provide additional validation data if requested

Coordinate with FDA on modification implementation timeline

Establish ongoing communication procedures for post-market updates

Implementation Readiness:

Train implementation teams on PCCP procedures and requirements

Establish performance monitoring and reporting systems

Develop user communication and training materials

Prepare for initial modification deployment and assessment

Ready to Navigate PCCP Implementation Successfully?

Predetermined Change Control Plans represent a paradigm shift in AI medical device regulation, enabling continuous innovation while maintaining safety and effectiveness standards. Companies that master PCCP implementation will gain significant competitive advantages through faster deployment of AI improvements and reduced regulatory burden.

Smart AI medical device companies partner with regulatory experts who understand both the technical requirements and strategic opportunities of PCCP implementation.

The Fastest Path to Market

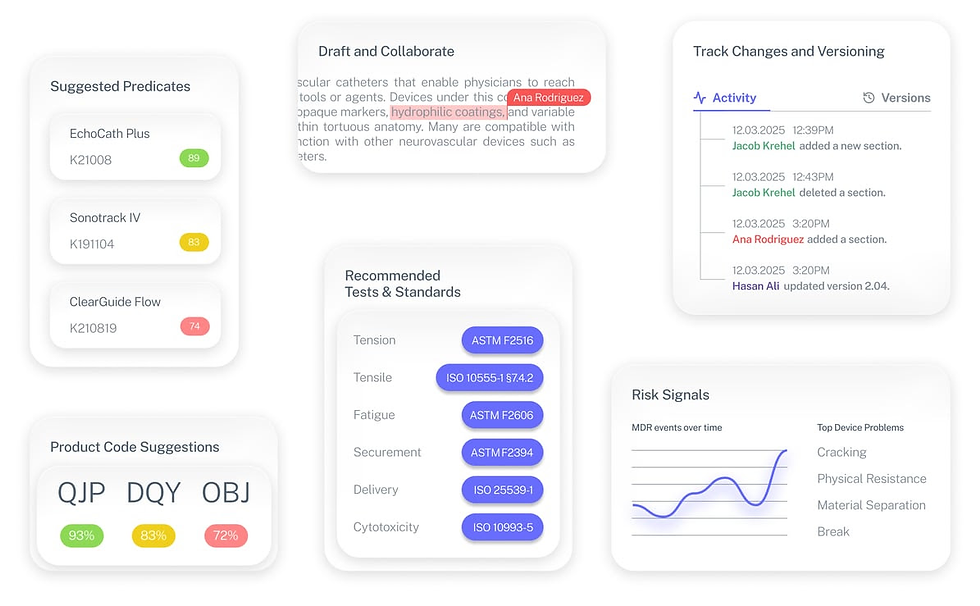

No more guesswork. Move from research to a defendable FDA strategy, faster. Backed by FDA sources. Teams report 12 hours saved weekly.

FDA Product Code Finder, find your code in minutes.

510(k) Predicate Intelligence, see likely predicates with 510(k) links.

Risk and Recalls, scan MAUDE and recall patterns.

FDA Tests and Standards, map required tests from your code.

Regulatory Strategy Workspace, pull it into a defendable plan.

👉 Start free at complizen.ai

Frequently Asked Questions

What types of AI device modifications require a PCCP versus traditional change control?

PCCP is appropriate for planned, iterative AI improvements within intended use boundaries. Traditional change control applies to unplanned changes, hardware modifications, or changes affecting device indications for use.

How does FDA review PCCP submissions differently from standard device submissions?

FDA evaluates PCCPs as part of the initial marketing submission, focusing on modification protocols, validation procedures, and impact assessments rather than reviewing each individual change.

Can we modify our PCCP after FDA approval of our initial submission?

PCCP modifications typically require supplemental submissions unless the changes are minor and within the original PCCP scope. Major PCCP changes may require new marketing submissions.

How do we handle modifications that exceed our approved PCCP scope?

Modifications outside PCCP boundaries require traditional change control procedures, potentially including Special 510(k), De Novo supplement, or PMA supplement submissions.

What happens if our PCCP modifications don't perform as expected?

PCCPs must include rollback procedures and failure response protocols. Performance monitoring requirements help identify issues early, and corrective actions should be documented and reported to FDA.